Project Brief

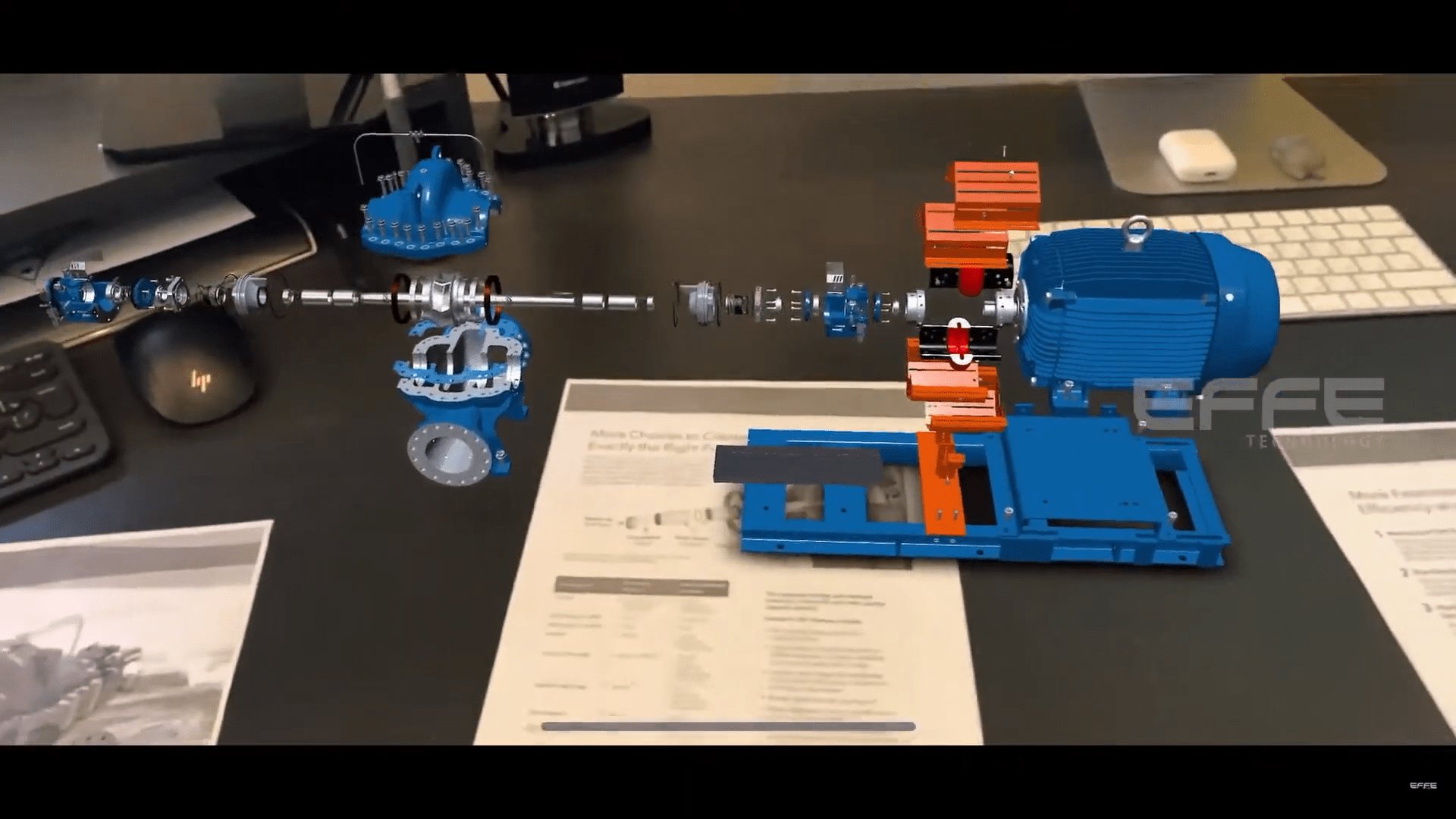

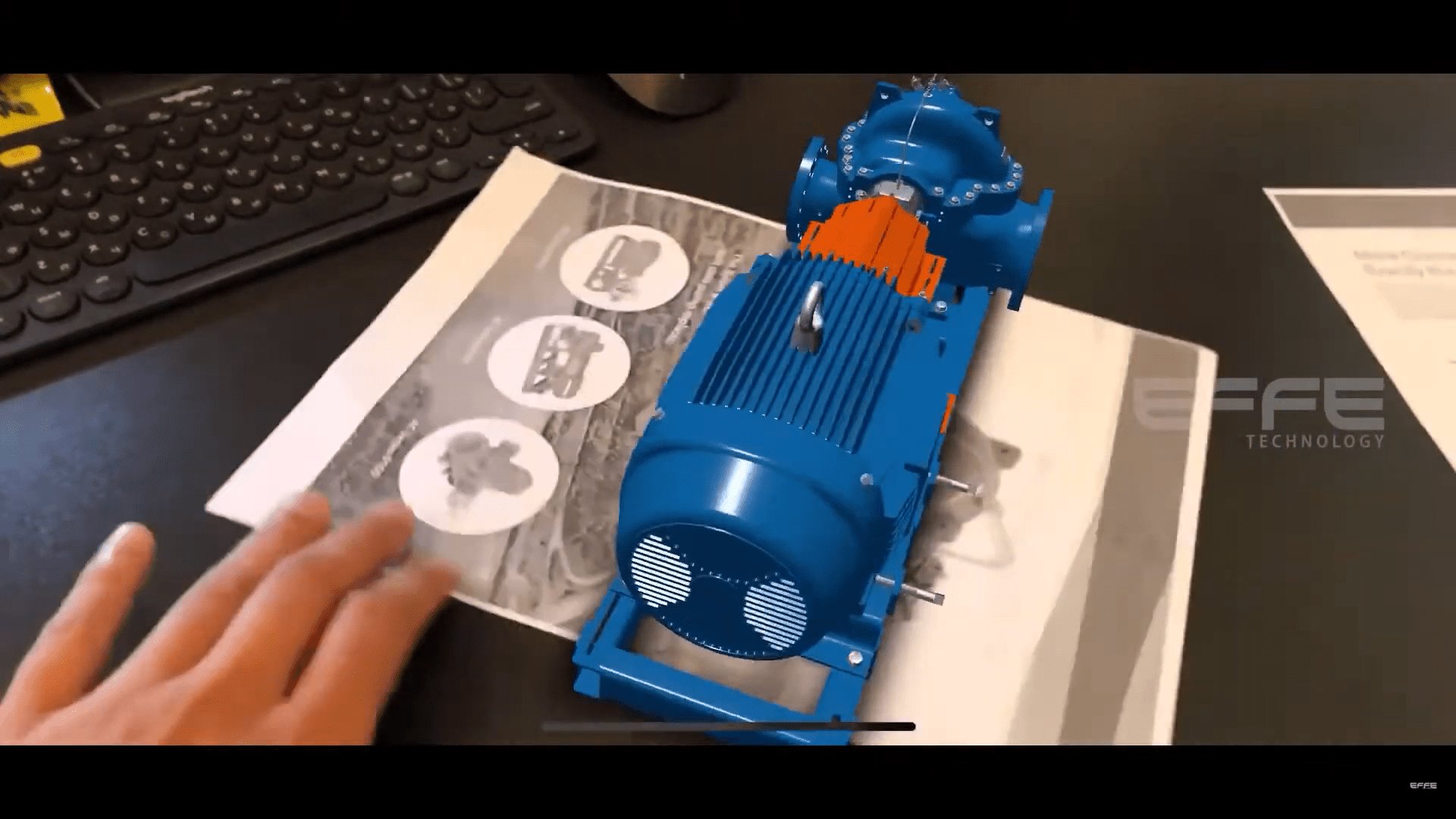

The manufacturing industry is undergoing rapid evolution, demanding innovative solutions like manufacturing with 3D AR visualization to optimize production and quality assurance processes. A leading motor valve manufacturer partnered with us to create an advanced Augmented Reality (AR) system tailored for real-time monitoring, troubleshooting, and 3D visualization of motor valve components. This initiative focused on enhancing operational efficiency, reducing downtime, and elevating staff training effectiveness.

Client Requirement

The client, a prominent motor valve manufacturer, faced significant challenges in streamlining their production workflows. They identified the transformative potential of manufacturing with 3D AR visualization and required a cutting-edge solution with the following objectives:

- 3D Visualization for Troubleshooting: The client sought an AR platform capable of creating detailed 3D models of motor valve components. This visualization would enable technicians to identify and resolve mechanical issues more efficiently.

- Improved Operational Efficiency: To combat delays in manufacturing and maintenance, the client required an interactive AR system to improve component monitoring and minimize downtime.

- Employee Training: The client aimed to empower their workforce through immersive AR tools that simulate motor valve assembly processes in real time.

- IoT Integration for Predictive Maintenance: They needed the AR solution to sync with existing IoT sensors for real-time performance metrics and proactive maintenance planning.

- Scalability and User-Friendly Interface: The application had to be intuitive for users with varied technical skills and scalable for future upgrades.

By implementing manufacturing with 3D AR visualization, the client sought to revolutionize their operations and achieve unparalleled productivity.

Project Planning, Strategy, and Process

To meet these goals, we employed the following phases:

Planning Phase

- Requirement Gathering: Conducted detailed discussions to identify workflow challenges and training needs.

- Technology Assessment: Explored AR-compatible hardware, software, and IoT integration solutions.

- Objective Alignment: Set measurable goals to enhance production efficiency and quality assurance.

Strategy

- Modular Development: The AR application was designed as modular units for troubleshooting, training, and maintenance, aligned with the concept of manufacturing with 3D AR visualization.

- IoT Integration: Real-time data visualization was made seamless with IoT devices.

- User-Centric Design: A user-friendly interface ensured smooth adoption across the workforce.

Our Process

- Design and Prototype:

- Developed 3D motor valve models using Maya and Blender.

- Built a prototype for AR visualization, overlaying real-time data.

- Development and Testing:

- Implemented AR simulations for troubleshooting and assembly procedures.

- Conducted usability testing to validate performance in a live manufacturing environment.

- Training and Deployment:

- Delivered immersive AR training modules.

- Rolled out the system in phases, addressing specific use cases before full-scale adoption.

This structured process ensured the seamless integration of manufacturing with 3D AR visualization into the client’s workflows.

Deliverables and Client Benefits

Deliverables:

- Advanced AR viewer application for motor valve visualization.

- IoT-enabled real-time data tracking system.

- Interactive training and maintenance modules.

Client Benefits:

- Enhanced Efficiency: Downtime reduced by 30% with streamlined troubleshooting via manufacturing with 3D AR visualization.

- Cost Savings: Maintenance costs minimized due to predictive insights.

- Improved Training Outcomes: Employees achieved proficiency through AR-guided tutorials. Visit Our Partner Site

Conclusion

This project underscores the power of manufacturing with 3D AR visualization in the industrial sector. By integrating AR and IoT technologies, we empowered the client with tools to enhance productivity, reduce errors, and improve workforce capabilities. The solution showcases the immense potential of AR in revolutionizing manufacturing processes.

Augmented Reality for manufacturing industry| AR VR development company| EFFE Technology