Project Brief

EFFE Technology was approached by a leading oil and gas company to develop a VR Oil & Gas Training application. The aim was to improve operational safety, provide real-time training for hazardous environments, and streamline maintenance procedures for workers involved in offshore drilling operations. The company needed an immersive, cost-effective solution to simulate high-risk scenarios, such as gas leaks, equipment failure, and emergency evacuations, while ensuring compliance with industry regulations

Client Requirement

The client sought a VR Oil & Gas Training solution that would:

- Train workers in a simulated environment without exposing them to real-world risks.

- Provide emergency response drills, such as oil spills, gas leaks, and fire hazards.

- Enable personnel to familiarize themselves with complex offshore platforms and machinery.

- Offer ongoing training and certification for new hires and experienced workers.

- Incorporate safety protocols, operational procedures, and environmental controls in a virtual space.

The client also required a user-friendly interface that could be accessed easily across different devices, with the ability to monitor trainees’ progress in real-time.

Project Planning, Strategy, and Our Process

- Needs Assessment: EFFE Technology began the project by conducting in-depth consultations with the client to understand their training needs, existing processes, and specific safety challenges. Our team identified key focus areas such as equipment operation, emergency response, and hazard identification.

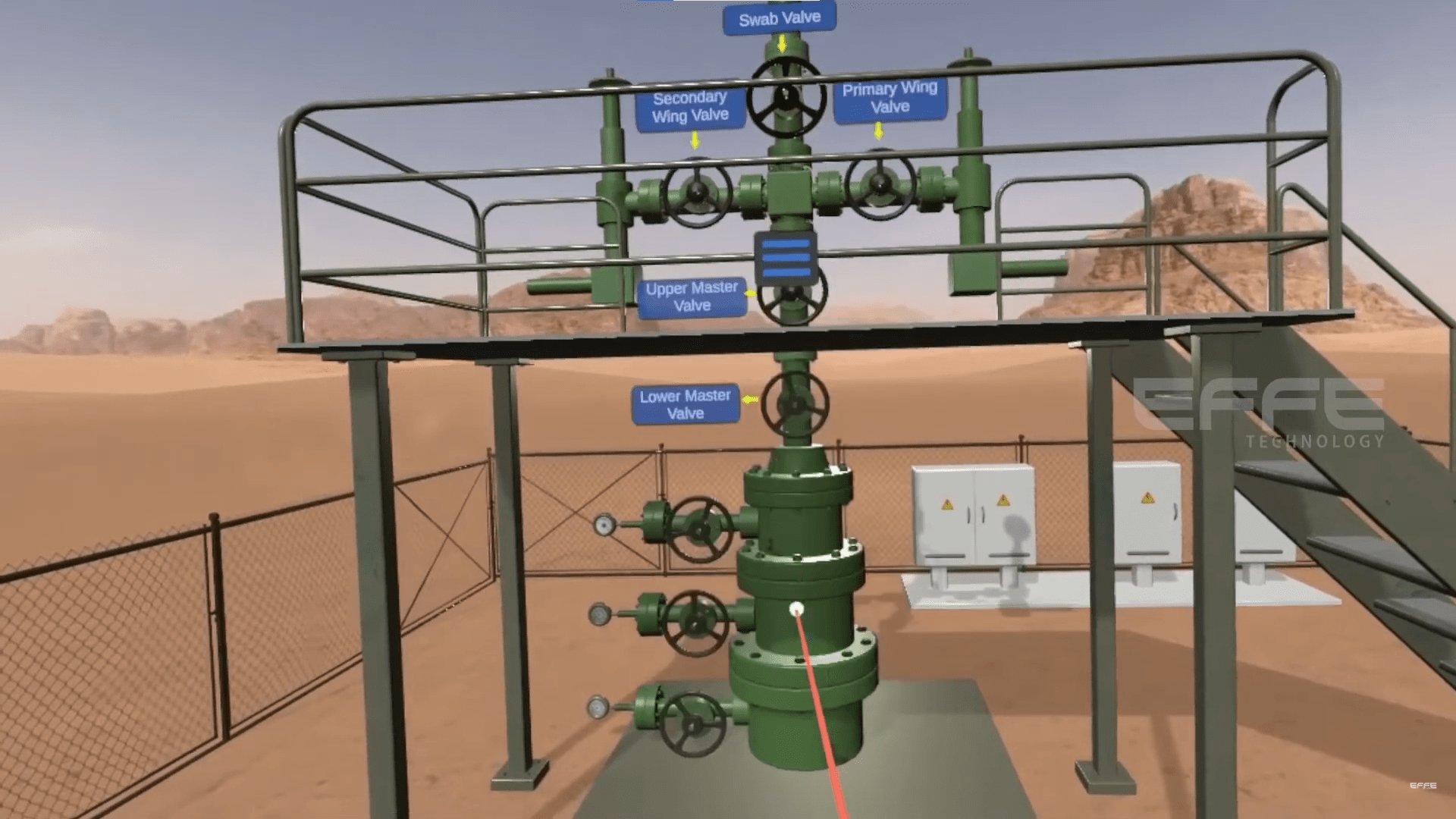

- Design & Development: The next step was to design a highly detailed and realistic 3D environment representing an offshore oil rig. This included creating virtual representations of machinery, safety equipment, and operational areas. We collaborated with industry experts to ensure the authenticity of the environment, making sure that all safety measures and operations were accurately depicted.

- Interactive Scenarios: To provide an immersive training experience, we developed interactive VR Oil & Gas Training scenarios where workers could engage with the environment. These scenarios included:

- Handling equipment malfunctions.

- Navigating hazardous zones during oil spills or fire emergencies.

- Performing routine safety checks and maintenance.

- Evacuating the platform in case of an emergency.

- User Interface and Navigation: The VR Oil & Gas Training platform was designed to be easy to use, allowing workers to navigate through the environment intuitively. A simple, yet functional, user interface was integrated to enable seamless interaction with the training modules.

- Performance Tracking: We integrated a real-time performance tracking system that monitored each trainee’s actions within the simulation. This allowed the client to evaluate the workers’ performance and provide feedback on areas for improvement. Analytics also helped track completion rates, overall progress, and areas where additional training was needed.

- Testing & Refinement: After the initial development phase, the application was tested in real-world scenarios. Pilot testing was conducted with workers, and based on their feedback, adjustments were made to improve the realism, interactivity, and training effectiveness. Visit Our Partner Site

Deliverables and Client Benefits

Deliverables

The final product was a fully immersive VR Oil & Gas Training application tailored to the oil and gas industry. The key deliverables included:

- Realistic 3D Environment: A high-fidelity virtual oil rig that replicated real-world offshore platforms, with realistic textures and interactive machinery.

- Emergency Response Training: Simulations of dangerous situations such as fire hazards, gas leaks, and equipment malfunctions.

- Hazard Identification: VR Oil & Gas Training scenarios where workers could identify potential hazards, such as equipment wear and tear, and unsafe conditions.

- Continuous Learning & Certification: A modular system that allowed for continuous training and certification, with customizable scenarios to meet industry standards.

- Safety Protocols & Guidelines: Integrated safety guidelines and protocols for all emergency scenarios, ensuring that workers learned the correct response for every situation.

- Monitoring & Reporting Tools: Performance tracking tools that allowed supervisors to monitor progress and provide real-time feedback.

Client Benefits

The VR Oil & Gas Training solution provided the following benefits for the client:

- Cost Savings: By eliminating the need for real-world hazard simulations and physical training sessions, the client saved on operational costs, travel expenses, and logistical challenges.

- Improved Safety: Training workers in a risk-free virtual environment significantly improved safety awareness and prepared personnel to handle dangerous situations with confidence.

- Increased Efficiency: Workers were able to practice complex procedures without the need for downtime or disruption to ongoing operations, improving productivity.

- Scalability: The VR Oil & Gas Training application could be used across various training centers and by employees worldwide, providing a scalable solution for ongoing education.

- Enhanced Compliance: The application helped the client comply with safety regulations by providing a structured, documented, and auditable training process.

Conclusion

EFFE Technology’s VR Oil & Gas Training application revolutionized how training is conducted in hazardous offshore environments. The immersive virtual platform provided a realistic and engaging way for workers to experience high-risk scenarios and practice their skills in a safe, controlled environment.

By using VR Oil & Gas Training technology, the client successfully improved training effectiveness, enhanced safety protocols, and reduced costs associated with traditional training methods. The ability to monitor progress in real time and evaluate performance provided valuable insights, which allowed the client to offer targeted, personalized training for their employees.

This innovative VR solution for the oil and gas industry represents a significant leap forward in worker training and safety, setting a new standard for industries dealing with high-risk environments. The use of virtual reality in the oil and gas sector not only ensures safer work conditions but also promotes operational efficiency and sustainability.

Virtual Reality application for Oil & gas industry| Application development company |EFFE Technology