Introduction:

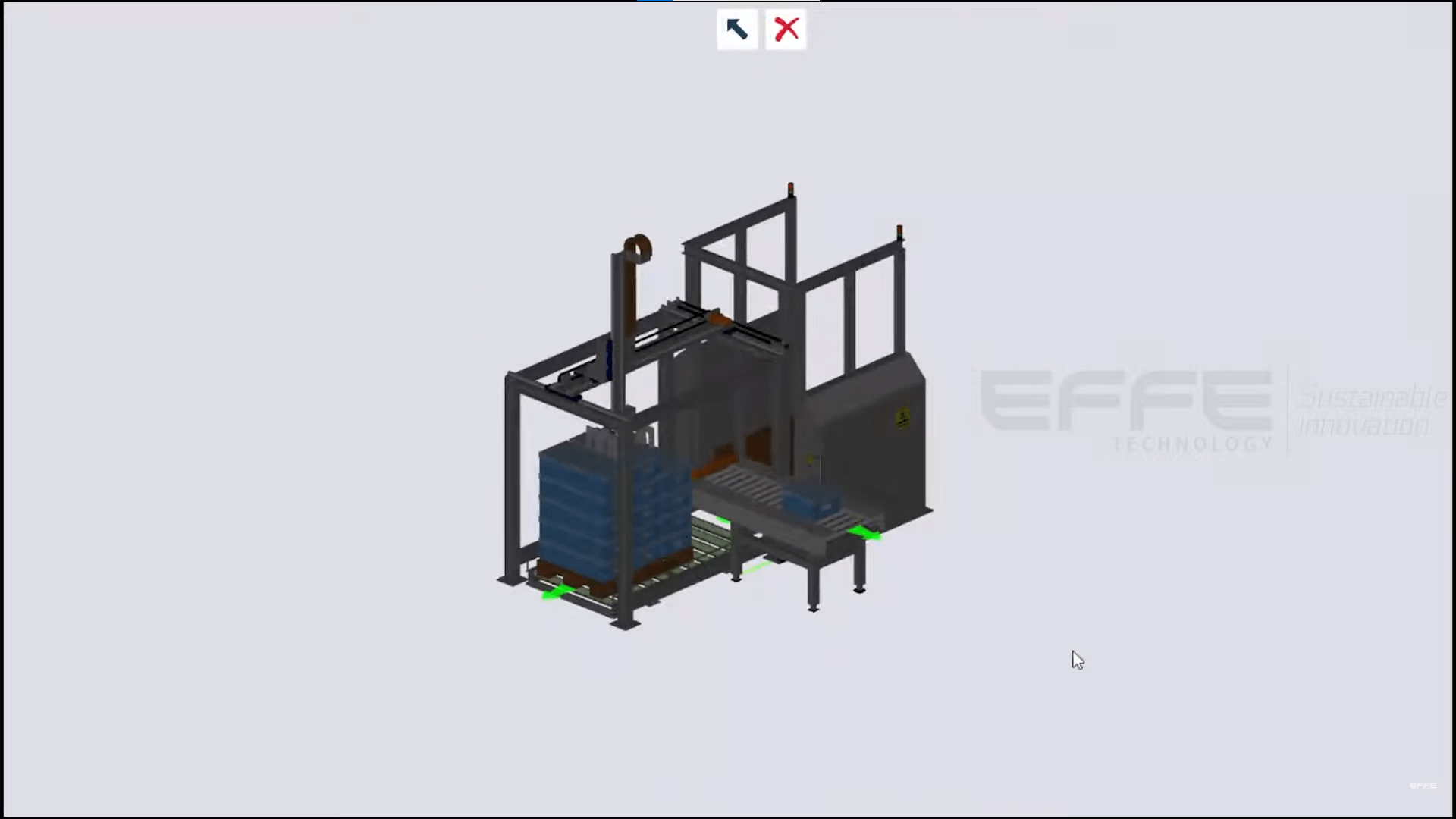

Packaging machinery plays a crucial role in the production and distribution of consumer goods across various industries. To enhance customer engagement and decision-making, EFFE Technology developed a 3D Configurator for Box and Packaging integrated with a 360-degree AR product viewer. The solution aimed to offer customers a comprehensive visualization of custom packaging machines, allowing them to explore, customize, and place orders efficiently and confidently.

Client Requirement:

The client, a leading packaging machinery manufacturer, sought to enhance their digital sales platform by providing an interactive tool for customers to customize and visualize their packaging machines. The objective was to offer a high level of customization for machines, enabling customers to select different features, sizes, and functionalities. The 3D Configurator for Box and Packaging had to incorporate real-time 3D rendering and AR capabilities, allowing customers to see their customized machines from every angle in a real-world environment.

Project Goals:

- Customization Flexibility: Enable customers to customize key features of packaging machines, including size, color, operational settings, and components through the 3D Configurator for Box and Packaging.

- Real-time 3D Visualization: Provide a dynamic, detailed 3D view of the machine with high-quality rendering, allowing customers to visualize their configurations accurately via the 3D Configurator for Box and Packaging.

- Augmented Reality Integration: Implement an AR feature that lets customers visualize the customized machine in a real-world setting, enhancing the decision-making process with the 3D Configurator for Box and Packaging.

- Cross-platform Access: Ensure the configurator is accessible across all devices—desktop, tablet, and mobile—making it convenient for a diverse user base. Visit Our partner Site

Development Strategy:

EFFE Technology used a combination of 3D modeling, AR technology, and responsive design principles to meet the client’s requirements. The development process was executed in the following phases:

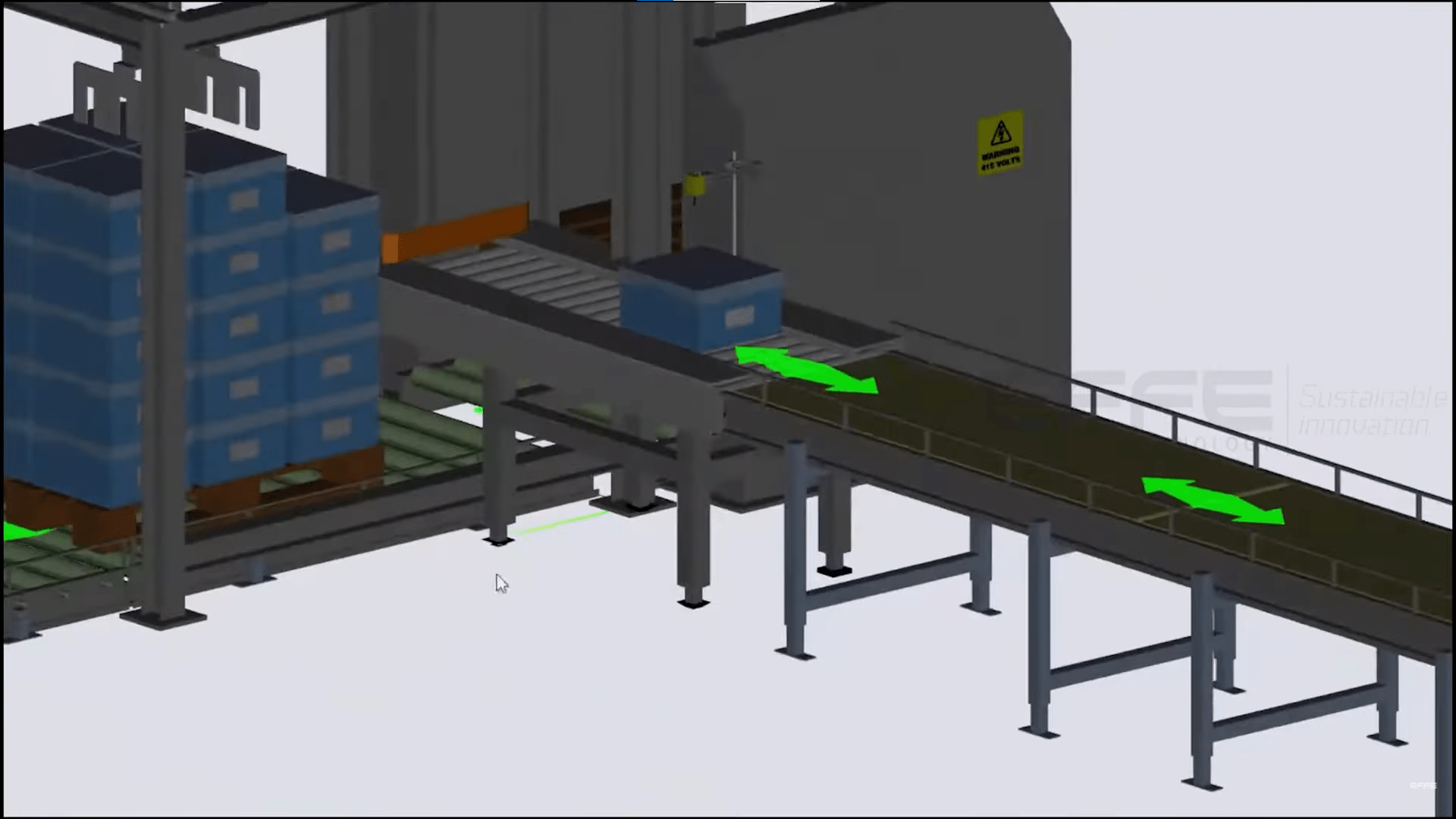

- Data Gathering and 3D Modeling: EFFE’s team collaborated closely with the client to gather detailed technical specifications and imagery of the packaging machines. Using this data, 3D models of the machines were created, ensuring that all parts, components, and configurations were accurately represented. This high level of detail was crucial for creating realistic visualizations that could be customized in real-time using the 3D Configurator for Box and Packaging.

- Configurator Design and Customization: The core functionality of the configurator focused on allowing users to customize various aspects of the packaging machine. These customizations included selecting machine size, adjusting components such as conveyors, and choosing operational settings like speed and capacity. The 3D Configurator for Box and Packaging featured a user interface designed to be intuitive, with an easy-to-use drag-and-drop system for adding and removing machine parts.

- 360-Degree Product Viewer Integration: To enhance the user experience, a 360-degree product viewer was integrated, allowing users to rotate the machine and explore it from every angle. This interactive feature helped customers understand the design and functionality of the packaging machine in a more immersive and engaging way, all within the 3D Configurator for Box and Packaging.

- Augmented Reality (AR) Functionality: One of the standout features of the configurator was the inclusion of AR technology. By leveraging ARKit and ARCore, EFFE integrated a feature that enabled users to project their customized packaging machines into real-world environments using their mobile devices. This was particularly useful for clients in industries like manufacturing and logistics, where space and machine dimensions are critical for decision-making. The 3D Configurator for Box and Packaging integrated this feature seamlessly.

- Cross-Platform Support: To ensure a seamless experience, the configurator was built to be responsive, functioning seamlessly across desktops, tablets, and smartphones. This ensured that customers could engage with the 3D Configurator for Box and Packaging from any device, enhancing its accessibility.

Solution Features:

- Real-time Customization: Customers could adjust the size, shape, and features of the packaging machine in real-time, with changes reflected immediately in the 3D model. This allowed users to experiment with different configurations without the need for lengthy consultations or manual design processes through the 3D Configurator for Box and Packaging.

- 360-Degree Viewing: The 360-degree viewer allowed users to explore the machine from every angle, providing a holistic view of the design. This feature helped eliminate doubts about the machine’s design and functionality, enabling customers to make informed decisions with the 3D Configurator for Box and Packaging.

- Augmented Reality (AR): The AR integration allowed customers to project their custom packaging machine into their real-world environment, giving them a better sense of scale and fit. This feature was particularly helpful for businesses that had specific spatial constraints in their production lines. This was all made possible with the 3D Configurator for Box and Packaging.

- User-Friendly Interface: The interface was designed to be intuitive, with easy-to-navigate options for customizing the machine. A simple click or drag of a component would update the 3D model in real-time, giving users an interactive and streamlined experience with the 3D Configurator for Box and Packaging.

- Seamless Integration: The configurator was integrated into the client’s existing website and ERP system, allowing seamless data transfer between customer selections and the production department. This streamlined the entire order process, from customization to manufacturing, through the 3D Configurator for Box and Packaging.

Client Benefits:

- Enhanced Customer Engagement: The interactive nature of the configurator encouraged deeper customer engagement. With the ability to visualize and customize packaging machines in detail using the 3D Configurator for Box and Packaging, customers were more likely to engage in the purchasing process.

- Improved Sales Process: The configurator shortened the sales cycle by providing customers with the tools they needed to finalize decisions quickly. The ability to see and adjust machine configurations in real-time meant fewer back-and-forth communications with sales teams using the 3D Configurator for Box and Packaging.

- Reduced Prototyping Costs: By allowing customers to visualize and customize machines digitally, the need for physical prototypes was minimized. This not only saved time and resources but also improved efficiency in product development, thanks to the 3D Configurator for Box and Packaging.

- Increased Confidence in Purchases: The AR feature provided customers with the confidence that the machine would fit within their space, minimizing uncertainty and improving their trust in the brand. Customers could be sure that their customized machine would meet their requirements before placing an order through the 3D Configurator for Box and Packaging.

Conclusion:

EFFE Technology’s 3D Configurator for Box and Packaging with 360-degree AR viewing capabilities has revolutionized how customers engage with and purchase packaging machinery. The combination of real-time customization, detailed 3D visualization, and AR functionality has created a more engaging and efficient sales process. Customers now have the ability to make informed decisions quickly, reducing lead times and increasing satisfaction. For businesses in the packaging industry, such innovations not only streamline operations but also position them as leaders in customer experience and technological advancement with the 3D Configurator for Box and Packaging.

Web application: 3D Packaging Machine Configurator | 360 AR Product Viewer | EFFE TECHNOLOGY