Project Brief

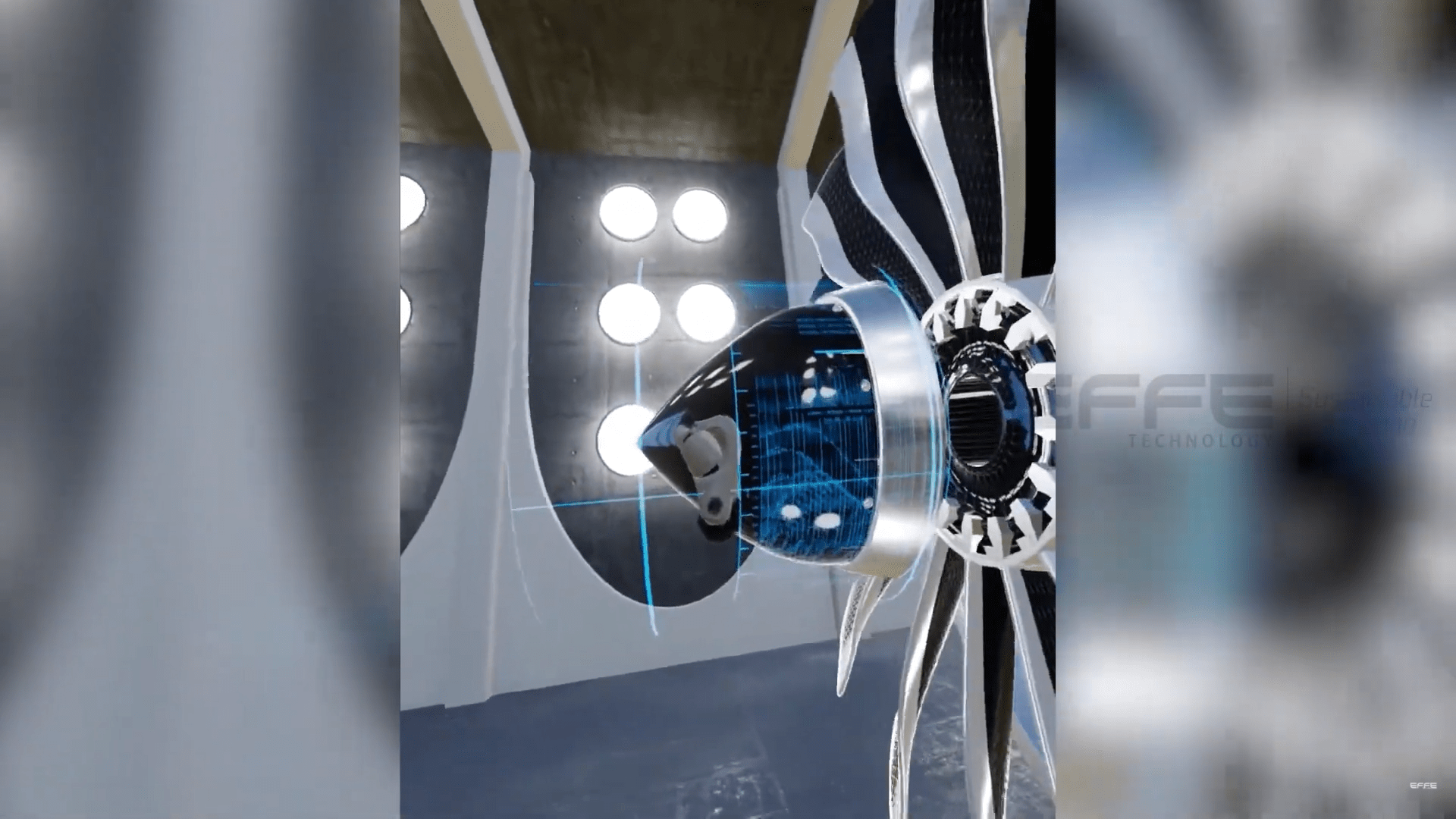

EFFE Technology developed a cutting-edge Virtual Reality (VR) training module for a leading aerospace company. The project aimed to provide immersive, interactive aircraft training with VR for technicians specializing in aircraft engine assembly. This solution revolutionized traditional training methods, ensuring enhanced skill acquisition and reduced assembly errors. The VR training program incorporated detailed simulations of engine components, assembly processes, and troubleshooting scenarios, offering a realistic and engaging learning experience.

Client Requirement

The client, a global aerospace leader, faced challenges with conventional training methods for aircraft engine assembly. Their specific requirements included:

- Skill Enhancement

Develop an immersive training module that simplifies complex assembly processes, ensuring technicians gain hands-on experience without risking real equipment.

- Error Reduction

Minimize assembly errors by providing trainees with realistic simulations of intricate engine parts and assembly sequences through aircraft training with VR.

- Cost-Effective Training

Eliminate the need for physical prototypes and reduce material wastage through a virtual training approach.

- Remote Accessibility

Enable trainees from different global locations to access the training module without the need for centralized physical training centers, ensuring broad accessibility for aircraft training with VR.

- Real-Time Feedback

Incorporate performance tracking and feedback mechanisms to evaluate trainee progress and address skill gaps.

Project Planning, Strategy, and Our Process

- Requirement Analysis

Our team worked closely with the client to identify critical assembly tasks, challenges, and training objectives.

- 3D Modeling and Simulation

High-precision 3D models of the aircraft engine components were created, ensuring accuracy and detail. Simulations were designed to replicate real-world assembly conditions.

- Interactive Training Scenarios

The training module included step-by-step assembly guides, troubleshooting exercises, and interactive quizzes to engage trainees effectively in aircraft training with VR.

- Integration of Real-Time Feedback

A dynamic feedback system was integrated to monitor trainee performance, provide guidance, and track progress over time.

- Testing and Validation

The VR module underwent extensive testing with experienced technicians and industry experts to ensure its usability, accuracy, and effectiveness.

- Deployment and Support

The final VR training solution was deployed across the client’s training facilities, with comprehensive support provided for smooth implementation. Visit Our Partner Site

Deliverables and Client Benefits

Deliverables

- Immersive VR Training Module

A complete VR solution for aircraft engine assembly, including interactive training scenarios, 3D simulations, and real-time feedback for effective aircraft training with VR.

- Detailed 3D Models

High-quality visualizations of engine components and assembly processes for a realistic learning experience.

- Assessment Tools

Built-in performance tracking tools to evaluate trainee knowledge, skills, and progress.

- Technical Documentation

Comprehensive guides for trainers and trainees to optimize the use of the VR module.

Client Benefits

- Improved Training Outcomes

The interactive and immersive nature of aircraft training with VR ensured better understanding and retention of complex assembly processes.

- Reduced Assembly Errors

Trainees gained practical experience in a virtual environment, leading to fewer errors in real-world assembly tasks.

- Cost Efficiency

The VR solution eliminated the need for physical prototypes and reduced training-related expenses.

- Global Accessibility

The remote nature of the training module enabled the client to train technicians from multiple locations without logistical challenges.

- Enhanced Safety

By practicing in a virtual environment, trainees avoided potential risks associated with handling sensitive engine components during the learning phase.

- Real-Time Progress Monitoring

The integrated assessment tools provided trainers with valuable insights into trainee performance, enabling targeted interventions to address skill gaps.

Conclusion

The VR Aircraft Engine Assembly Training developed by EFFE Technology transformed the client’s training methodology, offering an innovative solution that met all their requirements and delivered exceptional results. By leveraging aircraft training with VR, the client achieved significant improvements in training efficiency, cost-effectiveness, and trainee skill acquisition. This project demonstrated the potential of virtual reality in revolutionizing the aerospace industry, paving the way for future innovations in training and development.