Project Brief:

In the competitive landscape of the manufacturing industry, companies continually seek innovative methods to enhance operational efficiency, reduce downtime, and improve workforce training. This case study explores the integration of AR application in manufacturing to address these objectives. By implementing advanced augmented reality (AR) solutions, the project aimed to streamline maintenance processes, optimize training programs, and elevate overall productivity.

Client Requirement:

The client, a leading manufacturer, identified several critical areas for improvement:

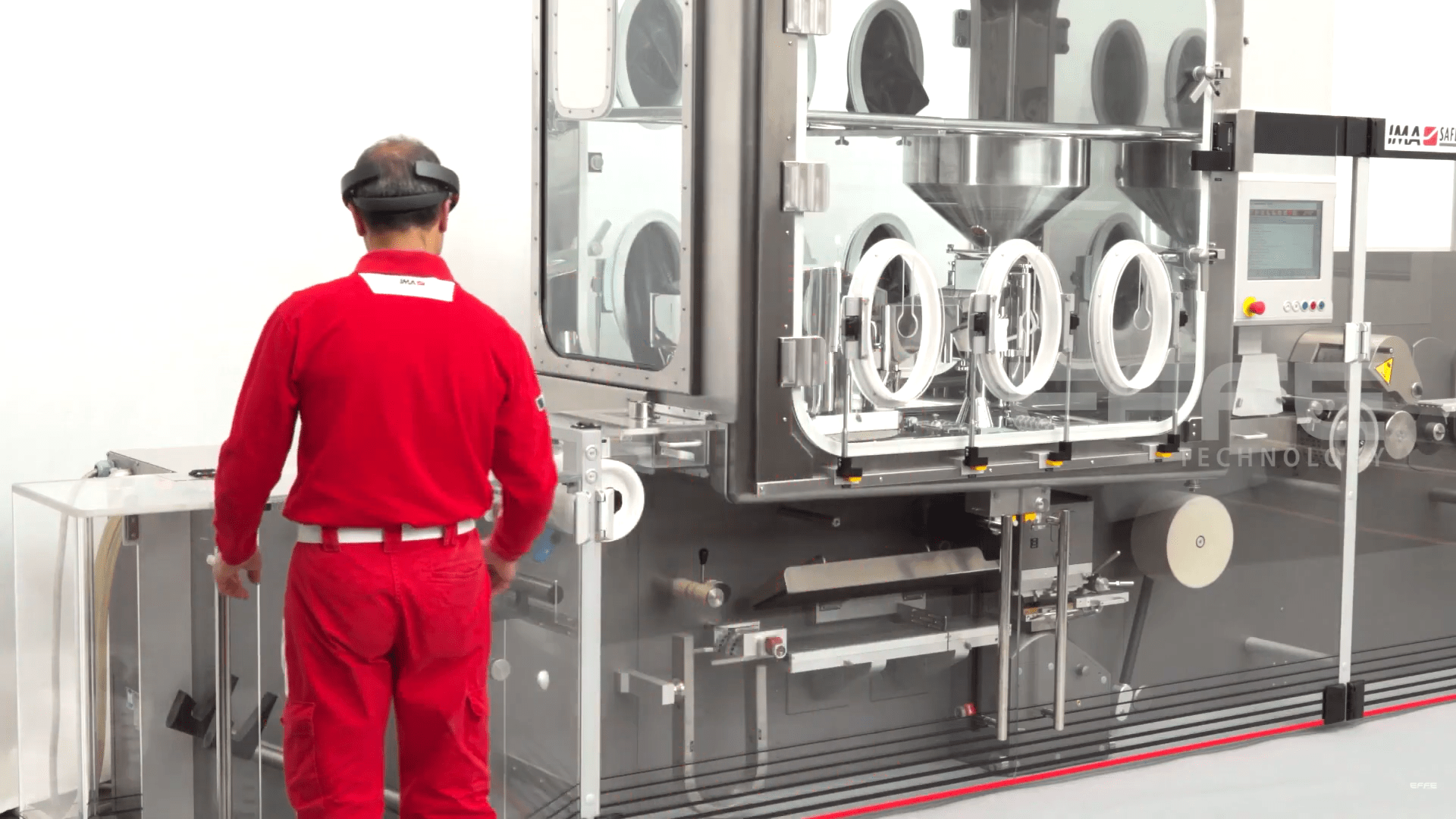

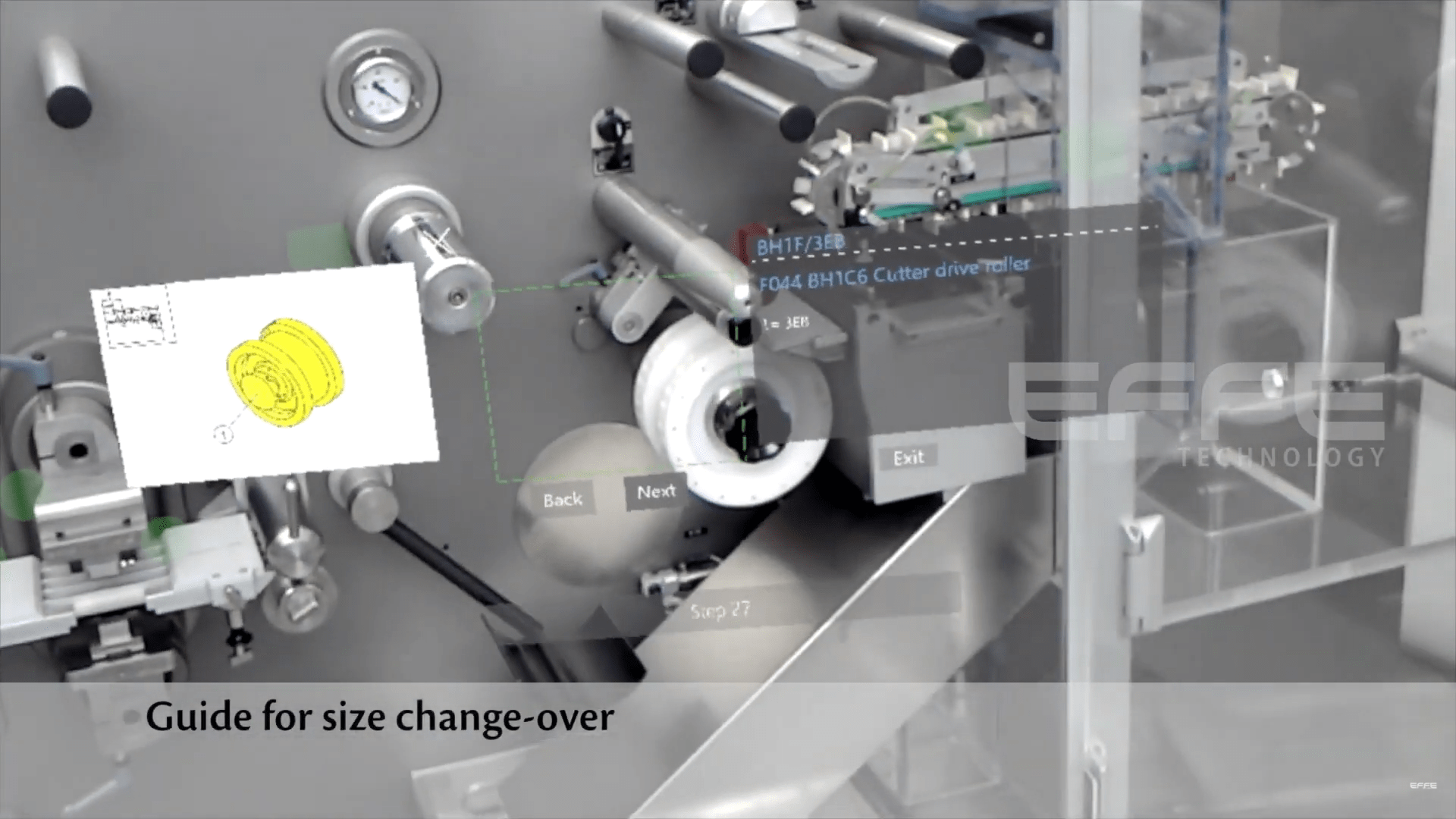

- Maintenance Optimization: The need for real-time AR application in manufacturing to assist technicians in diagnosing and repairing equipment swiftly, thereby minimizing downtime.

- Training Enhancement: Development of immersive AR-based training modules to expedite onboarding and upskill existing employees effectively.

- Operational Efficiency: Utilization of augmented reality services to provide workers with instant access to operational data and procedural guidelines, enhancing decision-making and reducing errors.

- Safety Protocols: Implementation of AR application in manufacturing to overlay safety information in real-time, ensuring compliance with safety standards and reducing workplace incidents.

Project Planning, Strategy, and Process:

To meet the client’s requirements, a structured approach was adopted, encompassing the following phases:

- Needs Assessment and Research: Conducted comprehensive consultations with the client’s management and operational teams to identify specific challenges and areas where AR application in manufacturing could be most beneficial.

- Design and Development: Leveraged insights from the assessment phase to design customized AR tools tailored to the client’s processes. This included AR mapping tools for equipment maintenance, interactive training modules, and real-time data visualization interfaces.

- Integration: Ensured seamless integration of the AR application in manufacturing with the client’s existing systems and workflows, addressing compatibility issues and ensuring data security.

- Testing and Validation: Piloted AR applications within select units of the manufacturing facility to test their effectiveness in real-world scenarios, gathering feedback to refine solutions.

- Training and Deployment: Developed comprehensive training materials and conducted workshops to ensure employees could effectively utilize the new AR tools. Rolled out solutions in phases for smooth adoption.

- Continuous Support and Improvement: Established a support framework for users and incorporated ongoing feedback into regular updates and enhancements to the AR applications in manufacturing.

Deliverables and Client Benefits:

Deliverables:

- Customized AR Application: Delivered augmented reality solutions tailored for maintenance, training, operational efficiency, and safety.

- Integration Documentation: Provided detailed documentation on how the AR application in manufacturing were aligned with existing systems.

- Training Materials: Created comprehensive resources and workshops for staff proficiency.

- Support Framework: Built a support system for ongoing assistance and solution improvements.

Client Benefits:

- Enhanced Operational Efficiency: The implementation of AR application in manufacturing reduced downtime and streamlined maintenance processes, increasing productivity.

- Improved Training Programs: Immersive AR-based training accelerated onboarding and upskilled employees effectively.

- Real-Time Data Access: Workers gained instant access to operational data and procedural guidelines via AR interfaces, leading to informed decision-making and reduced errors.

- Elevated Safety Standards: AR overlays provided critical safety information in real-time, reducing workplace incidents and enhancing compliance. Visit Our Partner Website

Conclusion:

The integration of AR application in manufacturing has proven transformative. Advanced AR solutions significantly improved operational efficiency, training effectiveness, and safety standards. This case study highlights the immense potential of AR application in manufacturing to revolutionize traditional processes, driving innovation and efficiency.

AR TECHNOLOGY FOR MANUFACTURING PROCESS | USING AR MAPPING TECHNOLOGY