Project Brief

EFFE Technology partnered with a leading oil and gas company to revolutionize their repair and maintenance processes through Virtual Reality for Oil & Gas. The oil and gas industry faces critical challenges, including high risks during on-site maintenance, extended downtimes, and substantial operational costs. To address these issues, the client required a technology-driven solution that could ensure safety, enhance efficiency, and minimize costs while equipping technicians with the skills needed to perform complex repairs effectively.

Client Requirement

The client needed a customized Virtual Reality for Oil & Gas application designed to:

- Enhance Technician Training: Train technicians to perform repairs and maintenance on complex equipment safely and effectively.

- Simulate Real-Life Scenarios: Offer immersive simulations that replicate real-life equipment malfunctions, emergencies, and repair processes in a controlled environment.

- Reduce Downtime: Provide technicians with the ability to practice and refine their skills virtually, reducing the time required for on-site troubleshooting and repairs.

- Ensure Safety Compliance: Familiarize technicians with safety protocols and procedures specific to high-risk environments in the oil and gas industry.

- Improve Accessibility: Make the application accessible remotely, allowing technicians to train anytime, anywhere.

- Integrate Performance Monitoring: Include assessment tools to evaluate technicians’ skills, identify areas for improvement, and track overall progress. Visit Our Partner Site

Project Planning, Strategy, and Our Process

- Requirement Analysis

EFFE Technology conducted a comprehensive analysis of the client’s maintenance processes, challenges, and training needs. We collaborated with their engineers and safety experts to ensure our Virtual Reality for Oil & Gas solution was aligned with industry standards. - Design and Development

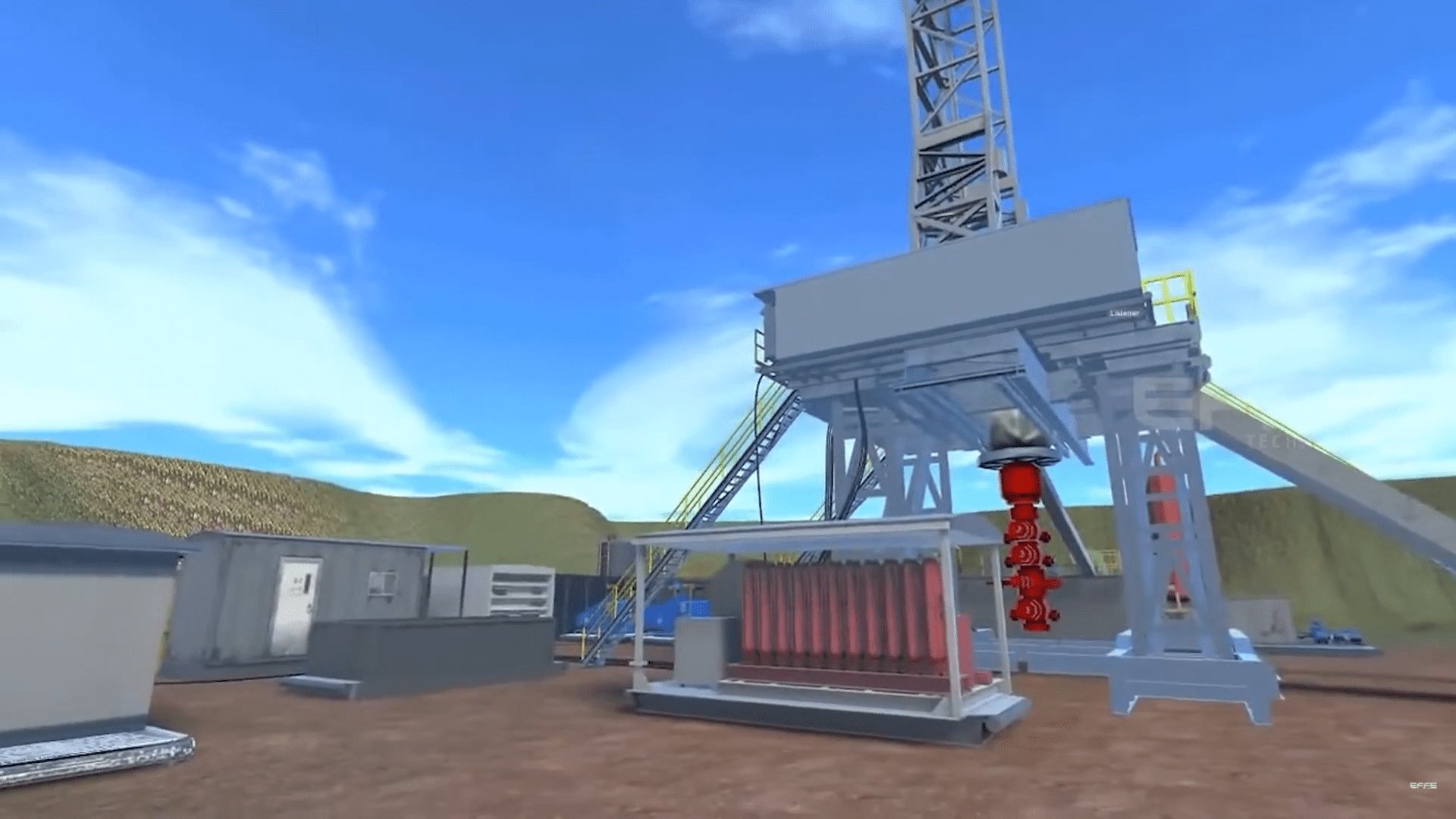

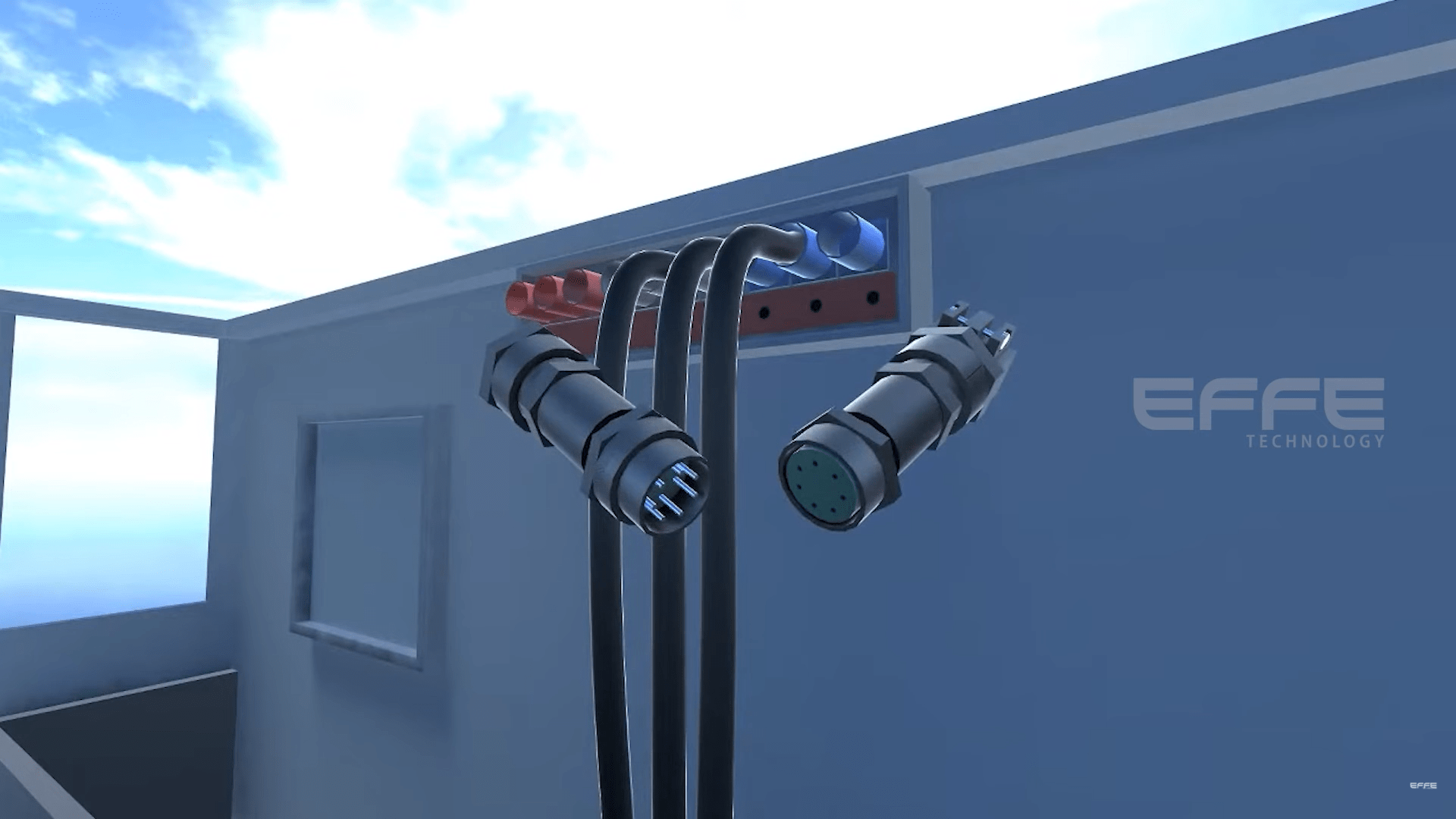

We designed a Virtual Reality for Oil & Gas application that simulated various repair and maintenance scenarios. The application featured:- 3D Equipment Models: Highly detailed 3D models of critical machinery and tools.

- Interactive Simulations: Real-time interactions with equipment to practice repairs, troubleshoot issues, and test solutions.

- Safety Modules: Simulations of emergency situations, such as equipment failure or hazardous leaks, to train technicians on safety protocols.

- Customization and Scalability

To ensure flexibility, the Virtual Reality for Oil & Gas application was built to allow for future scalability. The client could add new equipment models, training scenarios, or safety protocols as needed. - Testing and Feedback Loop

We conducted rigorous testing with a pilot group of technicians to refine the Virtual Reality for Oil & Gas application. Their feedback helped us make improvements, ensuring the application was user-friendly and effective. - Deployment and Training

The application was deployed on VR headsets and desktop platforms, making it accessible both on-site and remotely. We provided training sessions to familiarize technicians with the Virtual Reality for Oil & Gas system and its features.

Deliverables and Client Benefits

Deliverables

- Customized Virtual Reality for Oil & Gas application tailored to the oil and gas industry’s maintenance and repair needs.

- Detailed training modules covering common repair tasks, troubleshooting techniques, and safety protocols.

- Performance assessment tools to evaluate technician skills, monitor progress, and provide feedback.

- Scalable framework to update or expand training modules as needed.

- Multi-platform accessibility for immersive and remote training.

Client Benefits

- Enhanced Technician Preparedness: Technicians gained hands-on experience in a virtual environment, enabling them to perform repairs confidently and efficiently in the field.

- Improved Safety: By practicing emergency scenarios and safety protocols in VR, technicians were better equipped to handle high-risk situations, reducing workplace accidents.

- Reduced Downtime: Virtual training allowed technicians to refine their skills before working on-site, minimizing the time needed for actual repairs.

- Cost Savings: The Virtual Reality for Oil & Gas application eliminated the need for physical training setups, equipment rentals, and travel, resulting in significant cost reductions.

- Increased Accessibility: Remote training options allowed technicians to learn at their convenience, improving engagement and participation rates.

- Scalability and Long-Term Utility: The client could easily update the Virtual Reality for Oil & Gas application to reflect new technologies, procedures, or equipment, ensuring its relevance over time.

Conclusion

The Virtual Reality for Oil & Gas application developed by EFFE Technology transformed the client’s approach to repair and maintenance in the oil and gas industry. By leveraging Virtual Reality for Oil & Gas, we provided a safe, efficient, and cost-effective solution that improved technician skills, reduced operational risks, and enhanced overall productivity. This project underscores the potential of Virtual Reality for Oil & Gas technology to address industry-specific challenges, making it an invaluable tool for innovation and growth.

Virtual Reality application for Repair and Maintenance| Oil and gas industry| EFFE Technology